Contents Menu

GEARED MOTOR Cyclo DRIVE

The unique CYCLO speed reducing system is based on an ingeniously simple principle offering many benefits to the designer and user of power transmission drives.

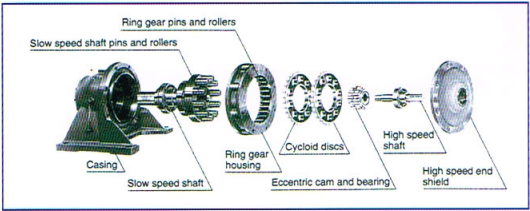

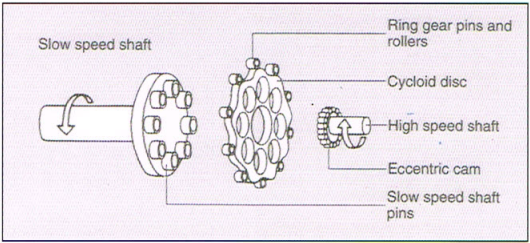

As the eccentric cam rotates, it rolls the cycloid discs around the internal circumference of the stationary ring gear. The resulting action is similar to that of a wheel rolling around the inside of a ring. As the wheel (cycloid disc) travels in a clockwise path around the ring (ring gear housing), the wheel itself turns slowly on its own axis in a counter-clockwise direction. In the CYCLO system the cycloidal profile around the outer edge of the disc engages progressively with the rollers of the fixed ring gear housing to produce a reverse rotation at reduced speed. For each complete revolution of the high speed shaft the cycloid disc turns one cycloidal tooth pitch in the opposite direction. In general, there is one less cycloidal tooth around the disc than there are pins in the fixed ring gear housing, which results in reduction ratios being numerically equal to the number of cycloidal teeth on the disc. (Note: On some ratios, there are two less teeth per cycloid disc than there are pins in the ring gear housing.) The reduced rotation of the cycloid discs is transmitted to the slow speed shaft by means of drive pins and rollers which engage with holes located around the middle of each disc. Normally a two disc system is used with a double eccentric cam which increases the torque capacity and offers an exceptionally smooth vibration-free drive.

PRODUCT FEATURES AND BENEFITS

CYCLO DRIVE®Brilliant engineering with unmatched performance advantages

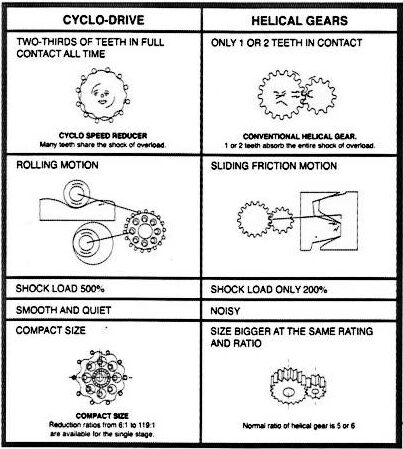

- COMPACT IN SIZE

The CYCLO can offer high ratio in a

single stage reduction (119/1) thereby

making the reducer size more compact

and lightweight. - HIGH EFFICIENCY

The CYCLO can offer ratio up to 119:1

on a single stage reduction at the same

time maintaining high efficiency

throughout. - NO CATASTROPHIC FAILURE

Due to the fact that the Cycloidal teeth

can not break, there is no chance for

the CYCLO to experience catastrophic

(Immediate) failure. - WIDE RATIO RANGE

CYCLO have the ratio range available

from 6:1 to 1,000,000:1 - LOW NOISE

As all parts are rolling. CYCLO

generate the lowest noise level.

- 500% OVER SHOCK LOAD

This photoelastic experiment clearly shows a number of cycloidal teeth

constantly in contact with the rollers, thereby distributing the loads.

Furthermore, the stress lines clearly sho hows no stress concentration in the root area.Unlike involute teeth, CYCLO teeth can not break.

- In the involute gear system, only one or two teeth are

engaged and are carrying the full load. There is a high

stress concentration in the root area of the teeth. Teeth

can break under shock load and overload.

ADVANTAGE OF CYCLO DRIVE

HOW IT WORKS

The unique CYCLO speed reducing system is based on an ingeniously simple principle offering many benefits to the designer and user of power transmission drives. Basically, the speed reducer has only three major moving parts :

As the eccentric cam rotates, it rolls the cycloid discs around the internal circumference of the stationary ring gear. The resulting action is similar to that of a wheel rolling around the inside of a ring. As the wheel (cycloid disc) travels in a clockwise path around the ring (ring gear housing), the wheel itself turns slowly on its own axis in a counter-clockwise direction. In the CYCLO system the cycloidal profile around the outer edge of the disc engages progressively with the rollers of the fixed ring gear housing to produce a reverse rotation at reduced speed. For each complete revolution of the high speed shaft the cycloid disc turns one cycloidal tooth pitch in the opposite direction. In general, there is one less cycloidal tooth around the disc than there are pins in the fixed ring gear housing, which results in reduction ratios being numerically equal to the number of cycloidal teeth on the disc. (Note: On some ratios, there are two less teeth per cycloid disc than there are pins in the ring gear housing.) The reduced rotation of the cycloid discs is transmitted to the slow speed shaft by means of drive pins and rollers which engage with holes located around the middle of each disc. Normally a two disc system is used with a double eccentric cam which increases the torque capacity and offers an exceptionally smooth vibration-free drive.

STANDARD SPECIFICATION

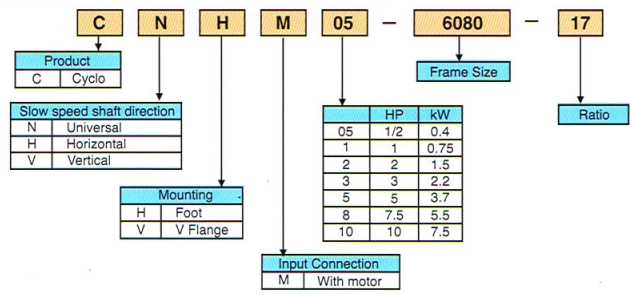

STANDARD STOCK OF GEAR MOTOR

HORIZONTAL TYPE (CNHM/CHHM)

| Output Speed (rpm) | MOTOR CAPACITY | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 HP (0.4 kW) | S.F. | 1 HP (0.75 kW) |

S.F. | 2 HP (1.5 kW) * |

S.F. | 3 HP (2.2 kW) |

S.F. | 5 HP (3.7 kW) |

S.F. | 7.5 HP (5.5 kW) |

S.F. | 10 HP (7.5 kW) | S.F. | ||

| 50 Hz | 60 Hz | ||||||||||||||

| 242 | 292 | CNHM05-6080-6 | 1.48 | CNHM1 -6090-6 | 1.53 | CNHM2-6100-6 | 1.57 | CNHM3-6110-6 | 1.61 | CNHM5-6120-6 | 1.37 | CHHM8-6130-6 | 1.71 | CHHM10-6135-6 | 1.51 |

| 132 | 159 | CNHM05-6080-11 | 1.48 | CNHM1-6090-11 | 1.53 | CNHM2-6100-11 | 1.57 | CNHM3-6110-11 | 1.61 | CNHM5-6120-11 | 1.37 | CHHM8-6130-11 | 1.71 | CHHM10-6135-11 | 1.51 |

| 97 | 117 | CNHM05-6080-15 | 1.48 | CNHM1-6090-15 | 1.53 | CNHM2-6100-15 | 1.57 | CNHM3-6110-15 | 1.61 | CNHM5-6120-15 | 1 37 | CHHM8-6130-15 | 1.41 | CHHM10-6135-15 | 1 20 |

| 85 | 103 | CNHM05-6080-17 | 1.48 | CNHM1-6090-17 | 1.53 | CNHM2-6100-17 | 1.33 | CNHM3-6110-17 | 1.45 | CNHM5-6125-17 | 1.53 | CHHM8-6135-17 | 1.51 | CHHM10-6145-17 | 1.60 |

| 69 | 83 | CNHM05-6085-21 | 1 38 | CNHM1-6095-21 | 2.01 | CNHM2-6105-21 | 1.52 | CNHM3-6115-21 | 1.41 | CNHM5-6125-21 | 1 29 | CHHM8-6135-21 | 1 22 | CHHM10-6145-21 | 1 27 |

| 58 | 70 | CNHM05-6090-25 | 1 68 | CNHM 1-6100-25 | 1.69 | CNHM2-6120-25 | 2.06 | CNHM3-6120-25 | 1.40 | CHHM5-6135-25 | 1.55 | CHHM8-6145-25 | 1.44 | CHHM 10-6165-25 | 1.79 |

| 50 | 60 | CNHM05-6090-29 | 1.56 | CNHM 1-6100-29 | 1.61 | CNHM2-6120-29 | 1.91 | CNHM3-6125-29 | 1 58 | CHHM5-6135-29 | 1.31 | CHHM8-6145-29 | 1 37 | CHHM10-6165-29 | 1 52 |

| 41 | 50 | CNHM05-6090-35 | 1.53 | CNHM1-610S-35 | 1.60 | CNHM2-6120-35 | 1.58 | CNHM3-6125-35 | 1.31 | CHHM5-6145-35 | 1.69 | CHHM8-6160-35 | 1.46 | CHHM 10-6165-35 | 1 28 |

| 34 | 41 | CNHM05-6095-43 | 1 51 | CNHM 1-6105-43 | 1.44 | CNHM2-6125-43 | 1.56 | CHHM3-6135-43 | 1.52 | CHHM5-6145-43 | 1.26 | CHHM8-6165-43 | 1.42 | CHHM 10-6175-43 | 1.51 |

| Item | Standard Specification | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor | Capacity Range | 1/2 ~ 10HP 4P | |||||||||||

| Enclosure | Totally Enclosed Fan Cooled Type | ||||||||||||

| Degrees of Protection | IP55 | ||||||||||||

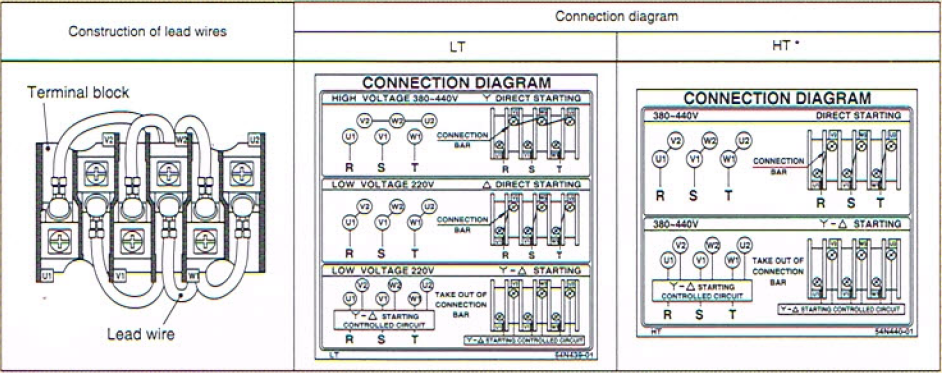

| Voltage and Frequency | - Low Voltage(LT) : 1/2~10HP= 220/380~415V 50Hz, 220/440V 60Hz | ||||||||||||

| - High Voltage(HT) : 5~10HP=380~415V 50Hz. 380~440V 60Hz | |||||||||||||

| Frame Meterial | Steel Plate | ||||||||||||

| Thermal Class | 155 (F) | ||||||||||||

| Rating | S1 (Continuous) | ||||||||||||

| Connection Type | Terminal Block (6 Leads) | ||||||||||||

| Connection Diagram |  |

||||||||||||

| Cyclo Drive | Lubrication Method | Grease Lubrication (Frame Size 6080~6125) Oil Lubrication (Frame Size 6130~6175) | |||||||||||

| Speed Reduction Method | Internal planetary gear mechanism with trochoidal curved tooth profile. | ||||||||||||

| Circumstance Condtion | Ambient Temperature | -20˚C~+40˚ | |||||||||||

| Ambient Humidity | 95% RH or less | ||||||||||||

| Above Sea Level | 1000 m.or less | ||||||||||||

| Environment | No bursting / erosive gas or vapor | ||||||||||||

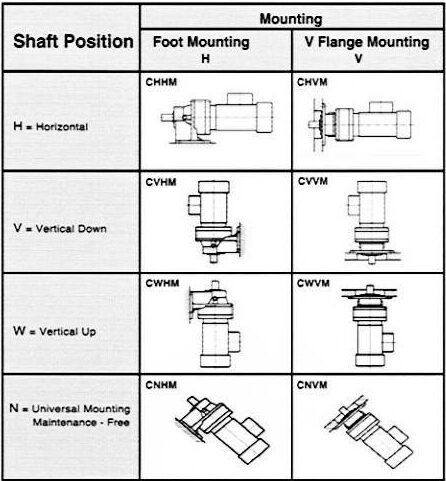

| Method of Mounting | CNHM / CHHM type : Slow speed shaft is in horizontal direction and mount horizontally on foot. | ||||||||||||

*HT can be used only with motors 5HP and above.

LUBRICATION

Recommended Grease

| Ambient temporature (˚C) | Model | ||||||

|---|---|---|---|---|---|---|---|

| Maintenance-free series | Other grease model | ||||||

| Shell | Cosmo Oil | Shell | |||||

| -10 ̴ 50 | ALVANIA GREASE RA | COSMO GREASE DYNAMAX SH No.2 |

ALVANIA GREASE 2 | ||||

Grease Quantity (litre)

| Frame size | 608 | 609 | 610 | 611 | 612 | |||

|---|---|---|---|---|---|---|---|---|

| Reduction portion | Q'ty of grease (G) | 65 | 90 | 140 | 200 | 330 | ||

| Slow speed shaft bearing portion | Q'ty of grease (G) | 70 | 100 | 100 | 90 | 120 | ||

Oil Quantity (lite)

| Frame size | 613 | 614 | 616 | 617 |

|---|---|---|---|---|

| Horizontal Shaft | 0.7 | 0.7 | 1.4 | 1.9 |

Recommended Oil

| Ambient temporature (˚C) | Nisseki Mitsubishi | Idemitsu Kosan | Gulf Oil | Esso Oil | Mobil Oil | Shell Oil | BP Oil | |

|---|---|---|---|---|---|---|---|---|

| -10 ̴ 50 | Bonnock M 68 | DapheSuper Gear Oil 68 | EPLubricant HD 68 | Spartan EP 68 |

Mobil Gear 626 (ISO VG 68) |

Omala Oil 68 | Energol GR-XP 68 | |

| 0 ̴ 35 | Bonnock M 100 , 150 | DapheSuper Gear Oil 100,150 | EPLubricant HD 100 HD150 | Spartan EP 100 EP 150 |

Mobil Gear 627 629 (ISO VG 100,150) |

Omala Oil 100 , 150 | Energol GR-XP 100 GR-XP 150 | |

| 30 ̴ 50 | Bonnock M 220 ̴460 | EPLubricant HD 220 HD320 HD460 | Spartan EP 220 EP 320 EP460 |

Mobil Gear 630 632 633 634 (ISO VG 220 ̴ 460) |

Omala Oil 220 320 460 | Energol GR-XP 220 GR-XP 320 GR-XP 460 | ||

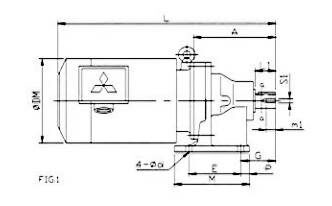

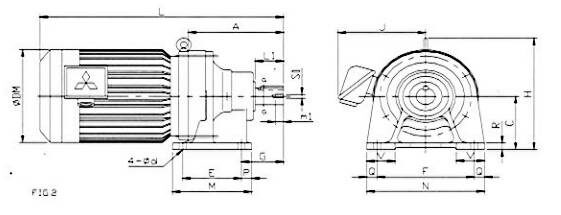

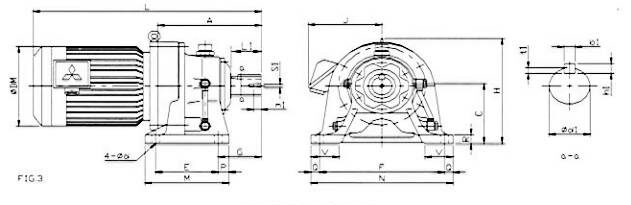

| FRAME SIZE | A | C | E | F | G | M | N | P | Q | R | V | d | SLOW SPEED SHAFT | H | DM | J | L | Weight (kg) | FIG | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | L1 | b1 | h1 | t1 | S1 | m1 | |||||||||||||||||||

| CNHM05-608 | 129 | 90 | 75 | 120 | 52 | 99 | 144 | 12 | 12 | 13 | 37 | 9 | 22h60-0.013 | 35 | 6 | 6 | 3.5 | M6 | 16 | 214 9 | 147.6 | 140 | 328 | 12 | 1 |

| CNHM05-609 | 142 | 100 | 90 | 150 | 60 | 135 | 180 | 15 | 15 | 12 | 40 | 11 | 28h60-0.013 | 35 | 8 | 7 | 4 | M8 | 20 | 248.9 | 147.6 | 140 | 345 | 15 | 1 |

| CNHM1-609 | 248 9 | 161.6 | 145 | 377 | 19 | ||||||||||||||||||||

| CNHM1-610 | 156 | 100 | 90 | 150 | 60 | 135 | 180 | 15 | 15 | 12 | 40 | 11 | 28h60-0.013 | 35 | 8 | 7 | 4 | M8 | 20 | 262.9 | 161.6 | 145 | 391 | 23 | 1 |

| CNHM2-610 | 215.3 | 184 | 158 | 426 | 31 | ||||||||||||||||||||

| CNHM3-611 | 170 | 120 | 90 | 150 | 70 | 135 | 180 | 15 | 15 | 12 | 45 | 11 | 32h60-0.016 | 45 | 10 | 8 | 5 | M8 | 20 | 250.8 | 207 | 170 | 487 | 38 | 2 |

| CNHM2-612 | 186 | 120 | 115 | 190 | 82 | 155 | 230 | 20 | 20 | 15 | 55 | 14 | 38h60-0.016 | 55 | 10 | 8 | 5 | M8 | 20 | 250.8 | 183.6 | 158 | 456 | 41 | 1 |

| CNHMJ-812 | 250.8 | 207 | 170 | 503 | 45 | 2 | |||||||||||||||||||

| CNHMS-612 | 250.8 | 228 | 182 | 513 | 55 | ||||||||||||||||||||

| CHHM3-613 | 240 | 150 | 145 | 290 | 100 | 195 | 330 | 25 | 20 | 22 | 65 | 18 | 50h60-0.016 | 70 | 14 | 9 | 5.5 | M10 | 18 | 293.8 | 207 | 170 | 557 | 64 | 3 |

| CHHM5-613 | 295.8 | 228 | 182 | 568 | 74 | ||||||||||||||||||||

| CHHM8-613 | 304 | 228 | 182 | 617 | 84 | ||||||||||||||||||||

| CHHM10-613 | 304 | 266 | 210 | 617 | 93 | ||||||||||||||||||||

| CHHM5-614 | 280 | 150 | 145 | 290 | 120 | 195 | 330 | 25 | 20 | 22 | 65 | 18 | 50h60-0.016 | 90 | 14 | 9 | 5.5 | M10 | 18 | 305.8 | 228 | 182 | 588 | 75 | 3 |

| CHHM8-614 | 314 | 266 | 210 | 637 | 85 | ||||||||||||||||||||

| CHHM10-614 | 314 | 266 | 210 | 637 | 94 | ||||||||||||||||||||

| CHHM8-616 | 308 | 160 | 150 | 370 | 139 | 238 | 410 | 44 | 20 | 25 | 75 | 18 | 60h60-0.019 | 90 | 18 | 11 | 7 | M10 | 18 | 348.5 | 266 | 210 | 685 | 120 | 3 |

| CHHM10-616 | 348.5 | 266 | 210 | 685 | 129 | ||||||||||||||||||||

| CHHM10-617 | 352 | 200 | 275 | 380 | 125 | 335 | 430 | 30 | 25 | 30 | 80 | 22 | 70h60-0.019 | 90 | 20 | 12 | 7.5 | M12 | 24 | 403 | 266 | 210 | 729 | 155 | 3 |